- Home

- Products & Solution

- Plasterboard Plant

- Scoring and Cutting Unit

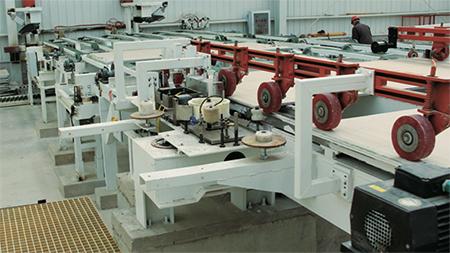

Scoring and Cutting Unit of Plasterboard Production Line

Consist of collecting belt, waste dry board roller, picking stacking machine, edge cutting and folding machine, lifting chain conveyor, positioning and aligning device, etc.

(Multiple solutions optional)

During scoring and cutting processes, dried plasterboard get sent to 2# broadwise conveyor by collecting belt conveyor. Waste dry board and over-length boards are picked out and discharged at the separating and stacking roller path after 2# conveyor.

Qualified dry boards will be sent to 3# broadwise conveyor, for edge folding and stacking.

Edge cutting system can cut one board a time or cut 2 or multiple (≧3) boards a time; cutting wastes can be used as coagulant after being squashed.

Edge folding system applies electric conical gluing roller and a paper constant tension adjusting stick, which effectively improves edge folding quality.

Two methods usually: one is commonly used:

The other is the method mentioned above, a palletizing platform with chain conveyor only, automatic packaging system can be attached.

①Mature and reliable controlling concept, effectively decreases;

②Reliable and effective safety protection system;

③Optional online humidity measuring system.

Get in touch with us Contact Us

Turnkey Plant Solution for Gypsum Plasterboard and Gypsum Blocks Processing

Turnkey Plant Solution for Gypsum Plasterboard and Gypsum Blocks Processing-

Address.: No.668, Guangfulin Road,Songjiang Industrial Zone, Shanghai City, China

Email:info@gypsum-machinery.com

Tel.:+86-21-51061761

Mobile:+86-131-6702-9626

Contact: Paul